Consumer & Special designed device

Peripheral Equipment GRIND-X Grining Stone

~We respond to various grinding conditions and draw 100% of the machine's capability~

GRIND-X Grinding Wheel

Feature

・ The purpose of grinding processing is to produce high quality workpieces with high accuracy and efficiency. Especially for grinding, choice of palm is a major factor determining quality.

Display symbol of standard abrasive grinding wheel

Selection method of grinding specification

We are aiming to make custom-made products that correspond to the material of the workpiece, required accuracy, and so on.

For details please consult GRIN - X 's catalog, your local sales office.

Peripheral equipment CBN・Diamond wheel

~Super abrasive grinding making superior accuracy with comfortable sharpness~

CBN・Diamond wheel

Feature

CBN/Diamond wheels are widely used for grinding difficult-to-grind materials, carbide ,brittle materials, as well as for profile grinding and groove grinding where wheel-shape-oriented grinding is preferred.

~Dynamic balancing of spindle system while the wheel being attached on the machine~

Micro balancer

Feature

・ Easy-to-understand dialogue. By following the instructions on the screen, you can easily and accurately perform balancing.

・ Because balancing is carried out with the brush attached to the machine in a rotated state, dynamic balance adjustment including unbalance of the machine and the shaft shaft system sensed by the vibration sensor is performed.

Peripheral equipment GRIND-X paper filter

~Extensive preparation of mesh according to application~

GRIND-X paper filter

Feature

・We have a variety of meshes according to the compatible size and application of the water filtering equipment with paper filter currently in use.

- It is used when filtering processing waste including nonmagnetic material and abrasive particle waste to improve surface quality.

Peripheral equipment Various dress equipment

~Various dressing equipment corresponding to various dressing methods prepared~

Small diameter R dress device

・ There are three reference center holes on the dress arm and it is possible to select turning R, so you can shorten the distance to the dress point and dress accurately.

・ Diamond tool has a structure that does not scratch, and accurate dressing is possible.

Side dress equipment

・ Since the diamond tool holding shaft rotates, the position (angle) can be set arbitrarily.

・ When the sharpness of the diamond tool deteriorates, it is possible to change the position by rotating the holding shaft.

Angle dress equipment

・ Angular shaping is possible from 0 to 45 ° and 45 ° to 90 ° using 2 rectangular reference surface.

・ Concave shaping of insecticide used for side grinding is also possible.

Side side & parallel dressing machine

・ Ideal for countersinking (escape) on side faces required for side grinding. Used for machine vertical movement and parallel dressing on side faces, shortening processing time

・ Accuracy improvement is possible.

Peripheral equipment GRIND-X grinding fluid

~Water-soluble grinding liquid excellent in antifoaming and resistance to decay~

GRIND-X grinding fluid

Feature

・ The grinding fluid has characteristics of "cooling property", "cleaning property" and "lubricity".

・ A lineup of products suitable for the shape, accuracy and processing method of the workpiece is available.

Peripherals GRIND-X Hydraulic oil

~Hydraulic fluid optimum for operation of grinding machine~

GRIND-X Hydraulic oil

Feature

・ It is designated hydraulic fluid which is adopted fully by our grinding machine. We recommend "GRIND-X Hydraulic Oil" for our grinding machine.

・ I will do oil change work. (Work cost is required separately)

Peripheral equipment Vertical rotary dresser

~CBN ・ Diamond wheels easily truing ・ dressing~

Vertical rotary dresser

Feature

・ In addition to the structure that supports the whetstone with the vertical shaft, the special design of the motor built-in realized 3 times the rigidity of the conventional product.

・ Truing can be done about 5 times faster than conventional products.

・ In the horizontal axis type, the dressing / truing condition changes due to the speed change due to the outer diameter decrease of the dressing toilet, but the condition does not change in the vertical shaft type.

※ To use this equipment, "Toy axle continuously variable transmission" is a required option.

Peripheral equipment rotary chuck

~Epoch making tool appeared after the sign bar chuck~

Vertical rotary dresser

Example workpiece

※ This photo contains options.

Feature

・ Innovative function expansion tool born from the mold manufacturing site. Rotating machining which is impossible in the past can be easily realized with high precision.

・ Semi-convex, medium concave machining is also possible by using the bar bar chuck. The forming grinding machine / surface grinding machine will be able to move in the same way as a small rotary grinding machine in 5 minutes.

Peripherals GRIND-X DIA Tools

~ Grinding quality changes with truing / dressing ~

DIA tool

Feature

・ Innovative function expansion tool born from the mold manufacturing site. Rotating machining which is impossible in the past can be easily realized with high precision.

・ Semi-convex, medium concave machining is also possible by using the bar bar chuck. The forming grinding machine / surface grinding machine will be able to move in the same way as a small rotary grinding machine in 5 minutes.

※ Dressing (dressing)

To crush the abrasive grains on the clogged face of the sprout to make a cutting edge.

※ Truing (reforming)

Make the shape of the palm concentric with the outer diameter of the brush and the center of the shaft.

Peripheral equipment GRIND-X SG master

~ Do not you have trouble with "warpage" ~

※ The standard specification is set with 9 slide blocks, 3 reference blocks and 4 stopper blocks.

Feature

・Easy setup

Instead of spacers, shims, bean jacks etc. used in conventional warpage work, it is possible to apply the magnetic force of the magnet chuck and hold the invisible surface of the material as it is.

・Suitable for all kinds of materials

Magnetic force is used only for holding jigs and is not transmitted to the material, so it is ideal for not only magnetic material but also non-magnetic aluminum, stainless steel, resin etc grinding.

・ Excellent planar accuracy

Grinding while retaining the incorrect surface of the material as it is, and also grinding while absorbing the strain during grinding ensures micron precision with a single grinding even for materials with large warp and twist.

Peripheral Equipment Cubitron II Grinding Wheel CUBITRON II

~ High grinding power ・ Long life force ・ Low heat generation ~

Handling size lineup

Φ200×19×Φ50.8

Φ300×38×Φ127

Φ350×38×Φ127

Φ400×50×Φ127

Φ500×50×Φ127

※We are preparing different kinds of specifications of each size.

Features What is CUBITRON TM II Wheel?

Ceramics with precision molded abrasive using 3M company's core technology "micro replication technology (high definition surface technology)". We propose efficiency ratio grinding by collaboration with rigid grinding machine of Okamoto Machine Tool Machinery Works.

Feature

・ Compared to the conventional case, the penetration input to the workpiece is high, and generation of grinding heat is suppressed. This enables deeper cuts and high-speed feed.

・ The dress characteristic which is said to be weak point of ceramic abrasive grain also improved. Regenerate the edge from the flat surface of the triangle to recover sharpness, dresser wear is also reduced.

・ In collaboration with Okamoto Machine Tool Machinery Works, there are examples of surface grinding machine, cylindrical grinding machine, internal grinding machine, compound cylindrical grinding machine, rotary grinding machine, gate type grinding machine, gear grinding machine. For details, please contact your sales representative.

※Cubitron TM II is a product of 3M company.

Peripheral equipment fine bubble generator GRIND-BIX

~ Change bubble, propose new common sense of grinding ~

Structure of GRIND-BIX

Feature

・ Coanda effect improves coolant / grinding fluid permeability

The swirling flow jet derived from the internal structure of GRIND - BIX ensured the grinding coolant liquid to spread to the tip of the abrasive grain by the Coanda effect, greatly improving the cooling capacity. As a result, cutting depth of 5 to 10 times is possible, contributing to reduction of machining time and improvement of accuracy.

(The effect varies depending on the workpiece, workpiece, and condition.)

・ Prevention of clogging of jaws by cavitation phenomenon

Secondary vibration when fine bubbles (bubbles less than several hundred nanometers in diameter) can be blown are constantly washed inside the pores, preventing clogging of the pins. As a result, the cutting edge is maintained, continuous grinding of several tens of microns is also possible without requiring sharpening even with # 2000 high mesh.

| Material of work material | SKD11(HRC57) |

|---|---|

| Workpiece outline | 200×200×20 |

| Usage Insertion | WA60K |

| Total grinding amount | 0.1mm |

| Cutting amount | 0.05mm |

| Machining time | 165 seconds |

| Surface roughness | Ra1.177μm |

※ The effect of GRIND-BIX differs depending on the model, processing work, and use.

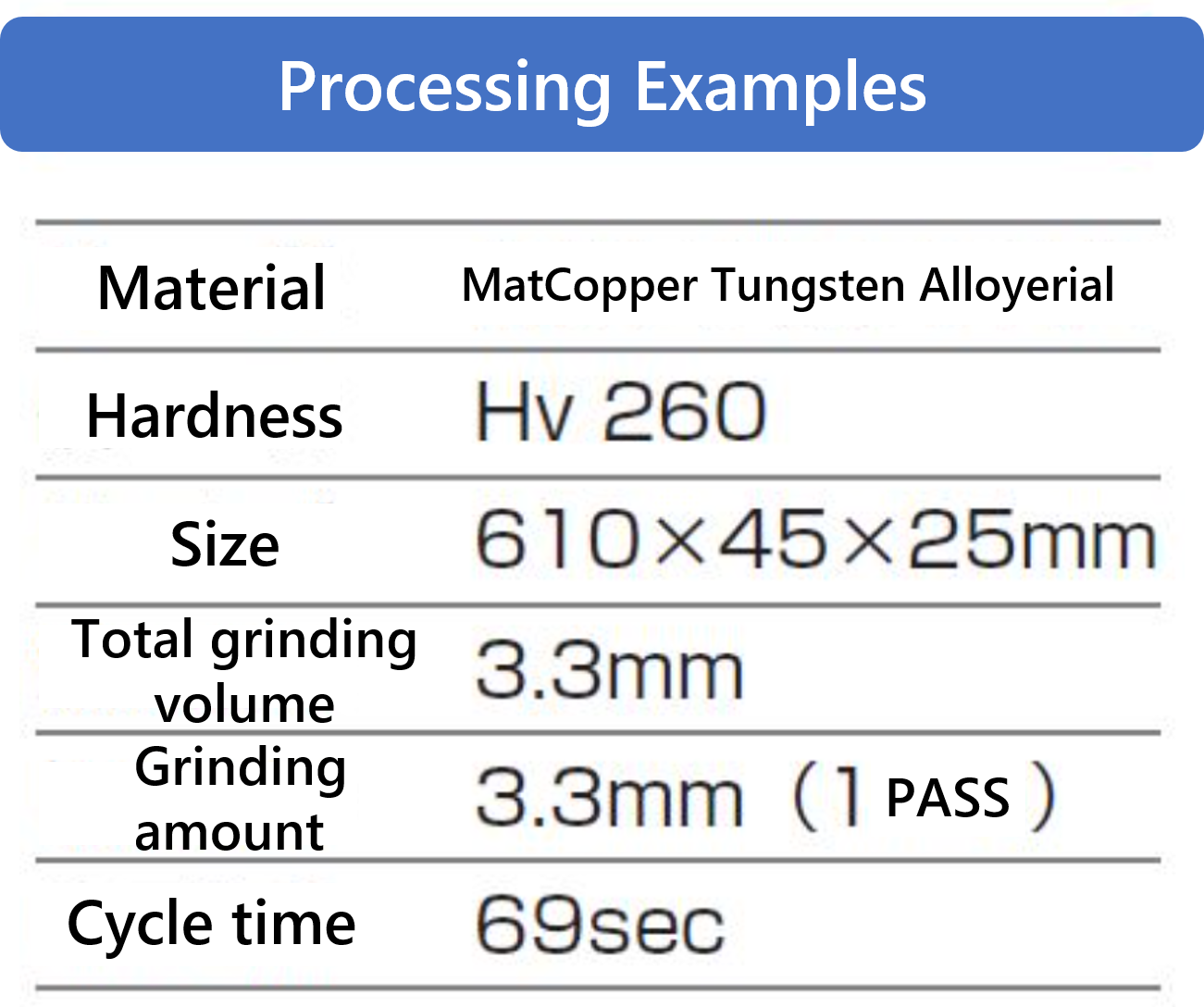

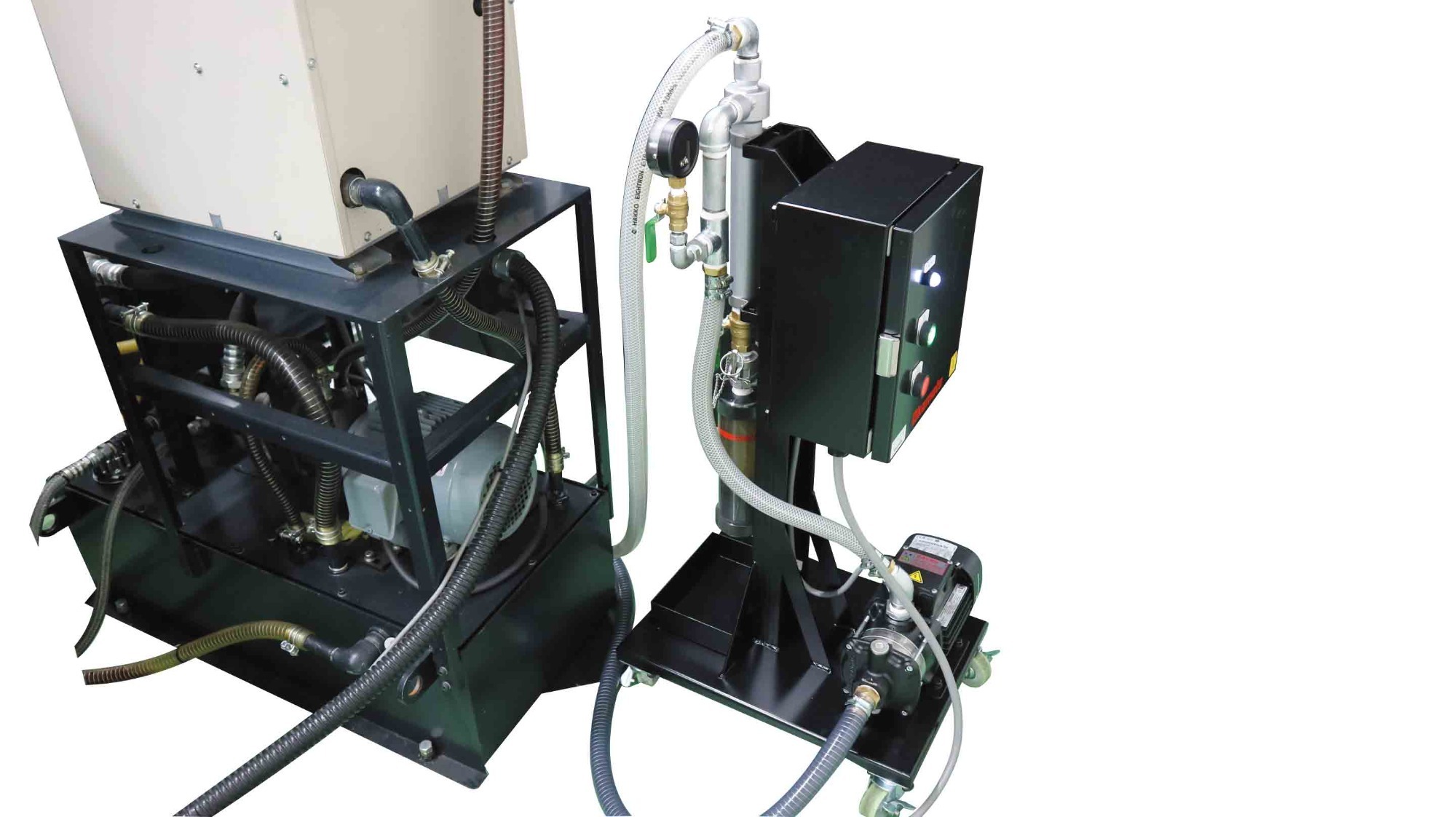

Peripheral equipment fine bubble generator TWIN-BIX

~ Incredible grinding efficiency. Reduce cycle time from general grinding. ~

Feature

・Prevent clogging of the grinding wheel due to cavitation.

・Coanda effect improves coolant penetration.

・TWINBIX's cooling effect is 30% higher than conventional BIX.

・Coolant permeates the grinding wheel to suppress heat generation.

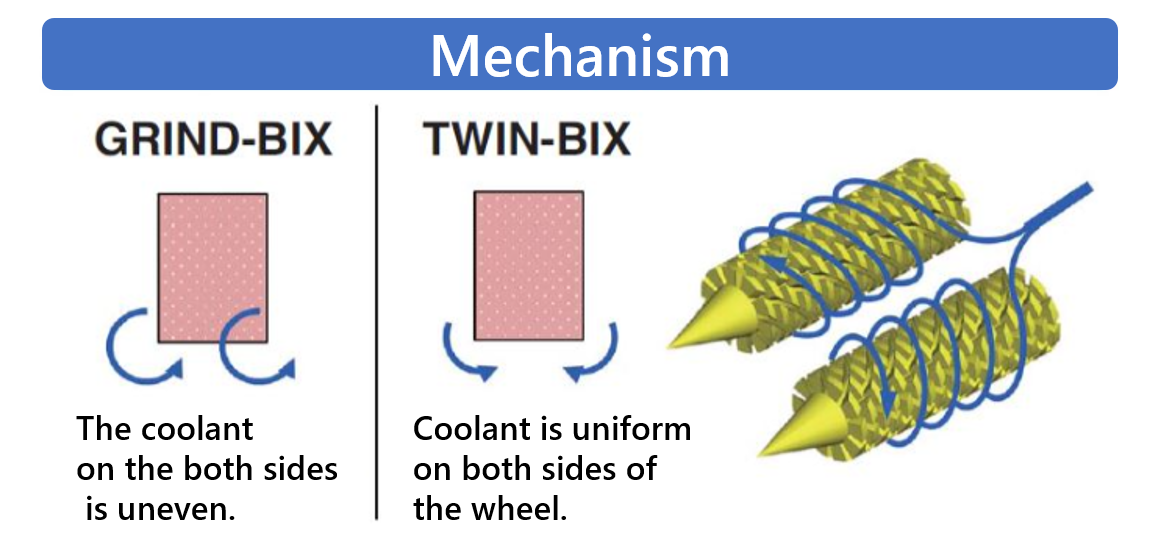

~ Mechanism for achieving high efficiency ~

Peripheral equipment Precision cylindrical grinding attachment MADOKAⅡ

Cylindrical grinding attachment MADOKAⅡ

Cylindrical grinding can be performed with a surface grinder.

Peripheral equipment Centerless grinding device GRIND-SMART

Centerless grinding device GRIND-SMART

・Centerless cylindrical grinding can be performed with a surface grinder.

・It is used for machining ejector pins of molds, etc.

Peripheral equipment Grinding process Peripheral equipment Vice equipment

Ultra precision right angle block

・ By developing the Ultra Screw which applies the screw rotating force only to one direction of pressing, the work can not be scratched and lifting at the time of work tightening can be prevented, so accurate chucking is possible.

In addition, by mounting the resin work guard on the Ultra screw, the soft material will not be scratched.

・ It can be used as a reference block only on the main body because of the full circumference high precision grinding finish.

Ultra triple tray Vice series

・ There is an integral type and a division type, but the UVH - 40 of the division type and integral type has a structure that can be corrected and chucking is possible arbitrarily.

・ It can be used as a reference block only on the main body because of the full circumference high precision grinding finish.

Stainless steel sign vice

・ Excellent characteristics not only in accuracy but also in abrasion resistance and rust resistance.

・ Gauge block is used for angle setting.

・ It is a mechanism to clamp the gauge block between the stage and the roller, and stable accuracy can always be maintained.

Stainless steel vise

Peripheral equipment Peripheral Ultra-Microfiltration Filters GRIND-FILTER

Ultra-Microfiltration Filters

GRIND-FILTER

~Suitable for microfiltration of ceramics, carbide and glass~

Feature

・Suitable for microfiltration of ceramics, carbide and glass.

・Since it is a bogie type, it can be retrofitted.

・Filter replacement is one-touch and easy to replace.

Before and after filtration of casting (FC system)

Peripheral equipment Stand-alone microfiltration equipment GRIND-ECO

Stand-alone microfiltration

GRIND-ECO

~Element paperless sustainable filtration equipment~

Feature

・Sustainable filtration equipment without elements or paper filters.

・Since it is a bogie type, it can be retrofitted.

・Available in a lineup of 100 V and 200 V power supplies, it can also be used to maintain coolant fluid in grinding machines.

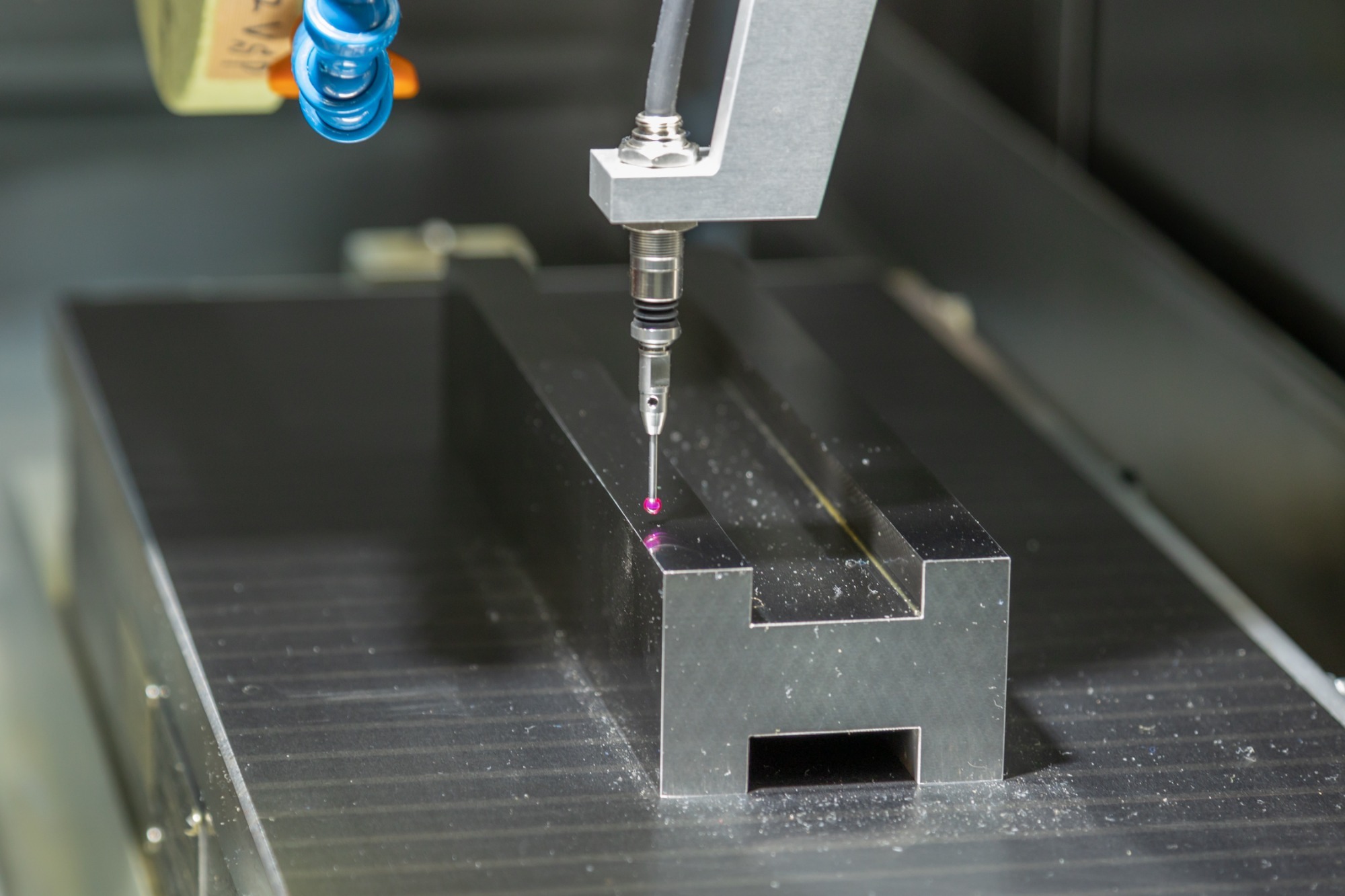

Peripheral equipment Instrument On-board Measurement Unit Quick Touch

Can also measure top and bottom dimensions and groove widths.

On-board Measurement Unit

Quick Touch

~Achieving high precision measurement easily and quickly on a grinder~

List of target series

CNC High Precision Molding Grinder HPG-NC Series

Precision surface grinder PSG-SA1 Series

Feature

・This is a unit option that allows easy and speedy on-board measurement with a surface grinder.

・No program required, measurement can be made just by touching the work measuring unit.

・It greatly contributes to the reduction of the remeasurement time of work and the operator's setup time.

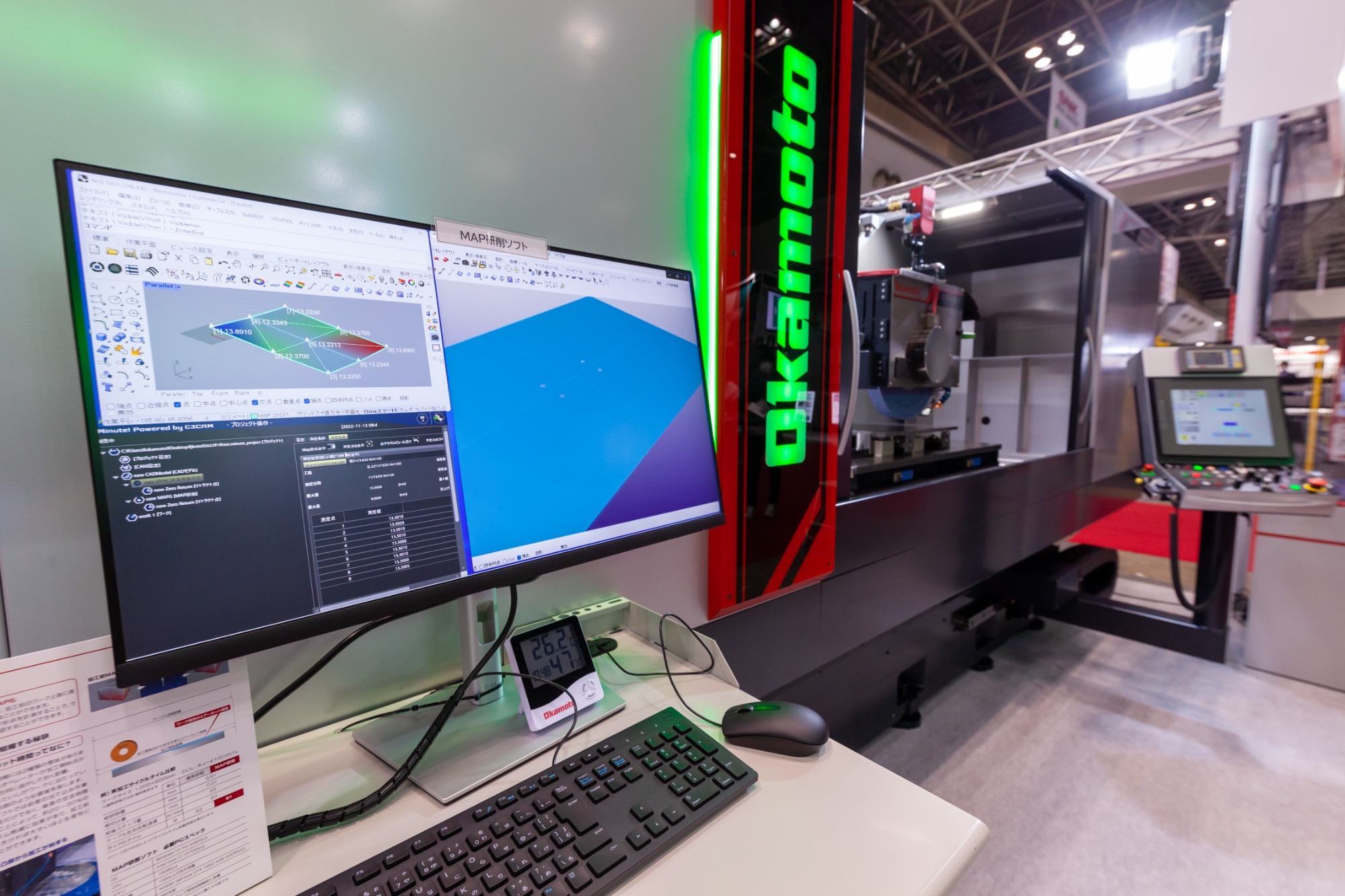

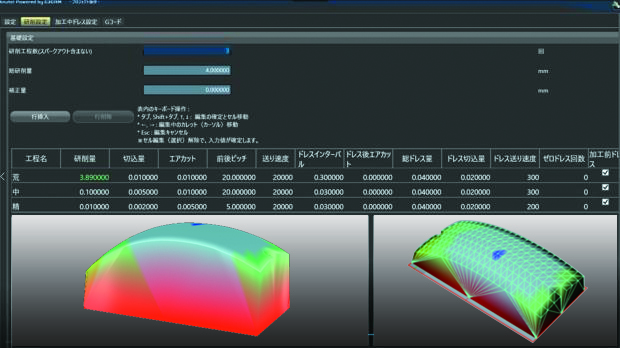

Peripheral equipment Fully Automatic Grinding System MAP Grinding Software

Fully Automatic Grinding System

MAP Grinding Software

~ Automation of onboard measurement and machining time is realized ~

Elevation difference image screen of work

List of target series

CNC Precision Surface Grinder PSG-CA3 Series

CNC ultra-precision surface grinder UPG-CHLi Series

Feature

・This is an optional surface grinder equipped with an onboard measurement unit.

・An automatic machining cycle is created after on-board measurement to automatically realize high-precision grinding.

・The on-board measurement results are converted to MAP, and the cycle time is drastically shortened by performing machining with the minimum required movement.

Peripheral equipment GRIND-X Yakibame Quill

GRIND-X Yakibame Quill

~ Up machining efficiency from cold forging die machining to fine precision drilling ~

Feature

・High precision hole machining support for IGM series of internal grinders.

・Significantly improved circularity/cylindricity/surface roughness compared to Collet formula.

・It can be used not only in grinders but also in high-precision machining centers.

Please contact us for various inquiries and information on the products of Okamoto Machine Tool Manufacturing Co., Ltd. from the following.