Precision Rotary Surface Grinding Machine

Precision Rotary Surface Grinding Machine Series

~Achieve high quality grinding from Single piece

to Mass production in high efficiency~

Precision Rotary Surface Grinding Machine

PRG6DX

※Photo shown with optional accessories.

SERIES line-up

PRG6DX・PRG8DX

CONCEPT

Original controller achieved 0.1µm infeed and is easy to operate.

Feature

・By adopting bridge (double column) structure, stable infeed and high precision is realized. Eazy loading/unloading due to lower position and wide open chuck area, because spindle unit traversing on double column slideway. Table designed lower position for easy loading/unloading; widen and open area for easy operation.

・Own developed controller is control Vertical infeed and Cross infeed by AC servo motor. Min. Vertical infeed setting is 0.1μm.

・Automatic cycle is Coarse grinding ⇒ Fine grinding ⇒ Spark-out ⇒ Step at workpiece peripheral end.Possible to chenge the settings of downfeed by step amount, table rotation speed, total remaining grinding allowance and variable speed even during automatic cycle, table step less speed.

Specification

PRG-DX series

CNC Precision Rotary Surface Grinding Machine PRG-DXNC series

CNC Precision Rotary Surface Grinding Machine Series

~Exert preeminent power in high-quality processing

from the single item to mass-produced products~

CNC Precision Rotary Surface

Grinding Machine

PRG8DXNC

※Photo shown with optional accessories.

SERIES line-up

PRG6DXNC・PRG8DXNC・PRG10DXNC・PRG12DXNC

CONCEPT

Standard interactive software enable grinding up to 4-steps grinding, grinding mode is traverse or plunge selectable.

Feature

・Adopt bridge (double column) type effect stable infeed, high accuracy. Grinding spindle travelling bridge (double column) slideway stable infeed without transformation.Table designed lower position for easy loading/unloading and wide open area for easy operation.

・Table can be inclined. Table inclined with simple operation, having convex or concave parts,taper shape or blade grinding.

・Necessary data input only and follow standard conversational screen, and to have automatic cycle is feasible.

Specification

PRG-DXNC series

Vertical Grinding Machine VRG-DX Series

Vertical Grinding Machine Series

~High-efficiency grinding leads to improved productivity~

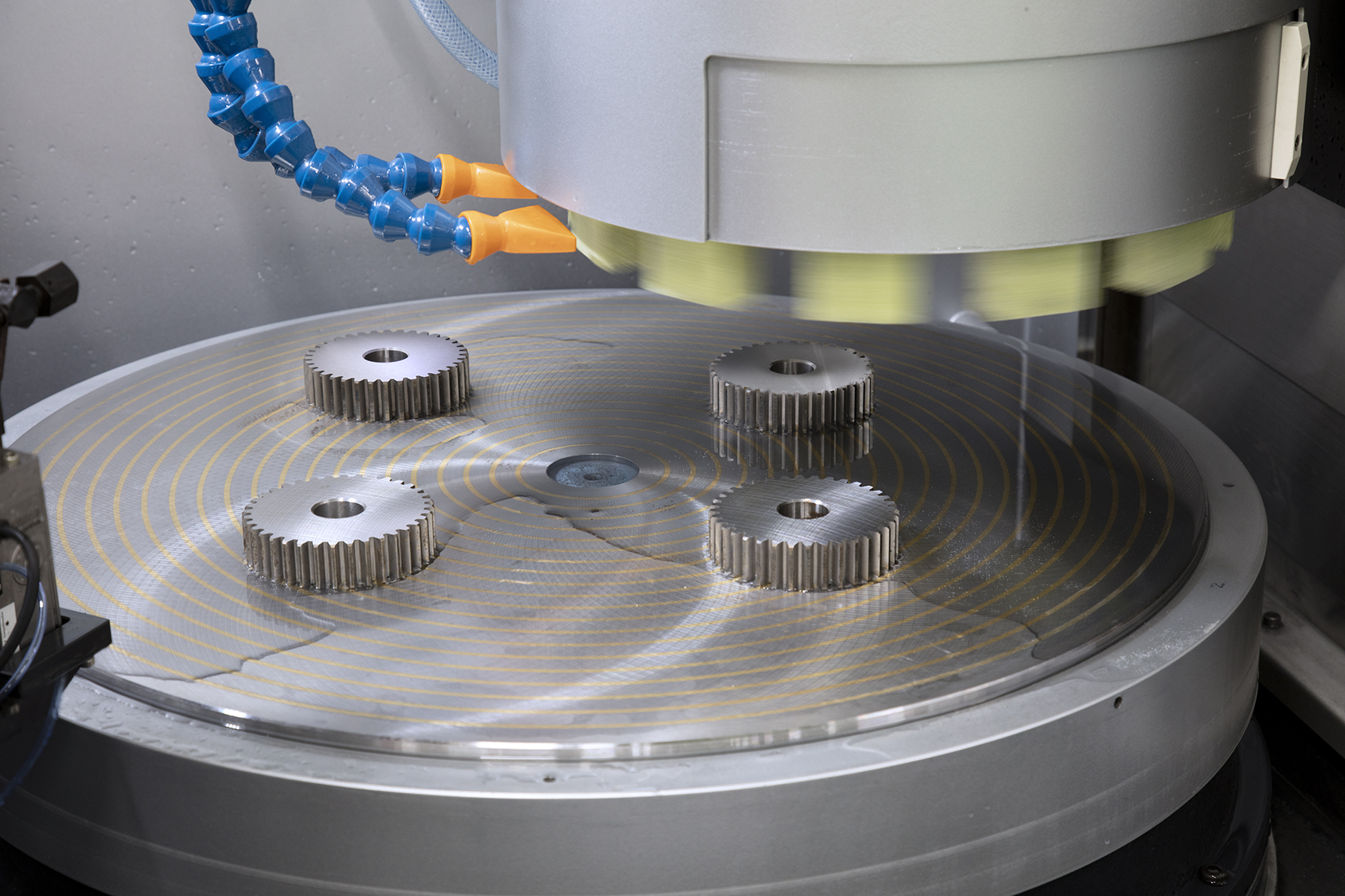

Vertical Grinding Machine Series

VRG6DX

※Photo shown with optional accessories.

※Machining time compared to our horizontal rotary grinder.

SERIES line-up

VRG6DX・VRG10DX

CONCEPT

High-efficiency and high-productivity grinding with vertical wheels.

Feature

・High-efficiency grinder series equipped with a rotary table and a vertical wheels.

・3-point support column structure for easy adjustment.

・Okamoto original FX controller can prevent operational mistakes with minimum number of intuitive operations.

・Fully closed cover adopted as standard for factory and work environment.

・Ideal for processing brittle materials such as glass/ceramics as well as metals.

Grinding multiple workpieces at the same cycle

Operation with a simple FX controller

CNC Ultra Precision Rotary Grinding Machine Model UPR3NC / UPR18NC

CNC Ultra Planarization Rotary Surface Grinding Machine

~Achieve more Ultra Precise and Higher Productivity~

CNC Ultra Precision Rotary

Grinding Machine

UPR3NC

CNC Ultra Precision Rotary

Grinding Machine

UPR18NC

(Specifications is negotiable)

※Photo shown with optional accessories.

SERIES line-up

UPR3NC・UPR18NC

CONCEPT

For high accuracy gap grinding with super high speed spindle unit, CD Rom die and precision blade, which are optimum for circular grinding.

Feature

UPR3NC

・Variable Hydrostatic slide system, Table air bearing can achieve 0.3μm/φ300mm Flatness & Parallelism.

・Adopted Air bearing have 0.05μm Radial & Axial rotation accuracy.

・Vertical downfeed is min. 10nm.

UPR18NC

Custom made machine specifically by application and demand.

Specification

UPR3NC series

Please contact us for various inquiries and information on the products of Okamoto Machine Tool Manufacturing Co., Ltd. from the following.